Bose Corporation The Jit Ii Program A Case Study

Bose Corporation: The JIT II Program. Documents Similar To 2. Sachin Kumar.

- Bose Corporation The Jit Ii Program A Case Study Solution

- Bose Corporation The Jit Ii Program A Case Study

- Bose Corporation: JIT II Case Solution,Bose Corporation: JIT II Case Analysis, Bose Corporation: JIT II Case Study Solution, This case provides students with the adjustments to the JIT (Just In Time) procurement.

- Bose Corporation, the brainchild of. MIT-professor Dr. Is where purchasing's JIT II' 1 comes in. Programs and can, with his expertise, influence. Through value analysis on the existing product base, the. With JIT II, some In-plants travel to the satellite to assist. G& FIndustry's Chris LaBonte, for example, is.

Bose Corporation estimates an unusual plan to manage relationships with suppliers, which supply components for speaker Bose. The company must decide: 1) what planning and ordering activities must be performed Bose, and that can be performed suppliers, 2) how many suppliers should have access to the Bose computer systems and structures, and 3) how to adapt relations with suppliers, as the company's growth or, as the market changes. Students are encouraged to consider both the buyer and seller's perspective on the buyer-seller relationship. 'Hide

by Roy D. Shapiro, Bruce Isaacson Source: Harvard Business School 13 pages. Publication Date: Mar 08, 1994. Prod. #: 694001-PDF-ENG

Related Case Solutions & Analyses:

Bose Corp.: The JIT II Program (A)

Bose Corporation The Jit Ii Program A Case Study Solution

September 01, 1998 By David Marble

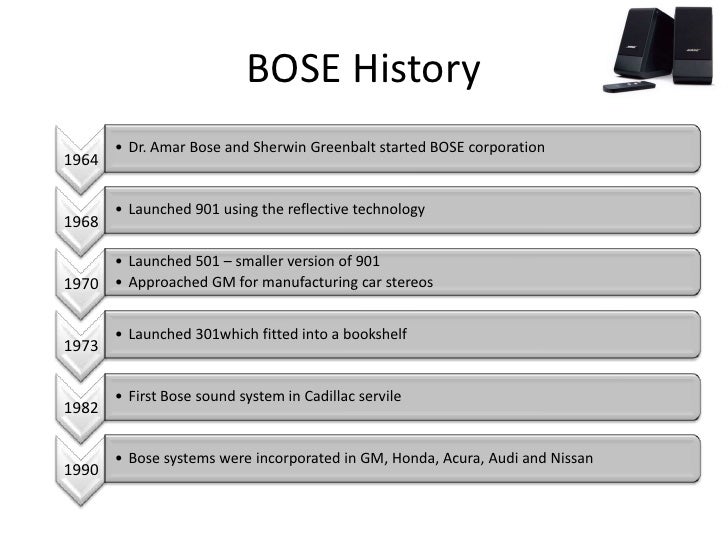

United Printing was in the unique position in 1986 to be part of Bose Corporation's now-famous JIT II experiment. Under this new approach to managing business logistics, Bose consolidated all its printing with one JIT II partner—United Printing—in exchange for immediate cost reduction, an inplant representative, and a defined ceiling on all pricing.

Twelve years later the JIT II 'experiment' is still going strong. The United Printing inplant still maintains an office in the Bose advertising department, with access to worldwide demands, constantly searching for efficiencies and cost reductions.

The inplant also places orders with manufacturing, and processes all the paperwork. Because the standards are already set, the task becomes one of eliminating duplication and errors, and maintaining a seamless direct-to-stock flow of printed material to Bose plants around the world.

Bose wants material when it is needed, not to sit in a warehouse. Responding to constantly changing production schedules without creating costly inventory, or even worse shutting down the line with late shipments, is United Printing's challenge. The direct line of communication in a JIT II partnership lets us anticipate Bose's needs before those needs become problems, and those problems become a crisis.

Before it started its JIT II program, Bose would forecast customer demand, set planning and specifications, then send that information out to buyers for competitive bidding. The company would analyze the bids and respond to the vendors' sales rep. The sales rep would place the order with the plant, which would manufacture and ship.

Under the JIT II program, however, the process is simplified. After Bose forecasts customer demand, the inplant checks every plant's inventory, combining and reducing unit costs for any other needs, then orders the product to ship direct-to-stock to the Bose location.

It takes a leap of faith to share and entrust your JIT II partners with the information they need to make it pay off for both parties, says Sherwin Greenblatt, Bose president. 'Everybody wins and performs better,' he says.

Stronger supplier alliances allow for more control over budgets and headcount. The benefits for the supplier include increased volume and the opportunity to expand the range of products offered.

JIT II partnerships also can prove to be a case study in faith. Early on in our relationship, Bose's Mexico plant had a spike in production. This demand called for the printing of $45,000 worth of products in a very short time. Here was a great opportunity to make a buck! The inventory was almost zero. This was no time for competitive bidding or old school methods.

United Printing's inplant went to work immediately, but not in the conventional sense. First, we searched the other plants' inventory to see what was readily available. Then we checked with the advertising department and found that this literature was going to be revised for the next printing. This told us that if we printed the ordered product, it would be obsolete in three weeks. But, knowing this did not negate the need for Mexico's production now.

The solution? The inplant was able to borrow enough stock from Bose's Ireland plant to keep Mexico going. This was accomplished with the help of Bose Fleet, which arranged the logistics.

The result?

- Bose did not spend $45,000 for product.

- The production line did not shut down.

- The product was revised.

- At the time of the new printing, the borrowed product was replaced with the new version at a lower unit cost because all demands were included in this production run.

Competitive bidding would not have saved 100 percent of the cost.

Twelve years into this unique JIT II arrangement, both partners continue to hone their skills. United Printing has stayed on the leading edge of commercial printing, and has added new services and technologies. The daily challenges of being a JIT II partner keep us sharp and alert to the marketplace, all as a result of Bose's original leap of faith.

Please enable JavaScript to view the comments powered by Disqus.Bose Corporation The Jit Ii Program A Case Study

Full Digital Issue

January 2019

(436 pages • 131.4 MB PDF)

Full Digital Issue

July 2018

(276 pages • 56.5 MB PDF)

Digital Edition

Sponsor Spotlight

(37 pages • 9.9 MB PDF)

Digital Edition

2019 Logistics Planner

(121 pages • 31.1 MB PDF)

Digital Edition

2018 Annual Third-Party Logistics Edition

(33 pages • 1.7 MB PDF)